Material reduction as a sustainable approach

Thinner, lighter, better –

using less is the new guiding principle

In recent years, we have steadily enhanced and developed our most important film types to achieve reductions in thickness as well as drastic material savings of up to 50 percent. This not only makes our current best sellers particularly resource-conserving, but also particularly sustainable – with even better performance.

At the same time, we always keep an eye on the development of sustainable packaging concepts. “Think outside the box” is our motto.

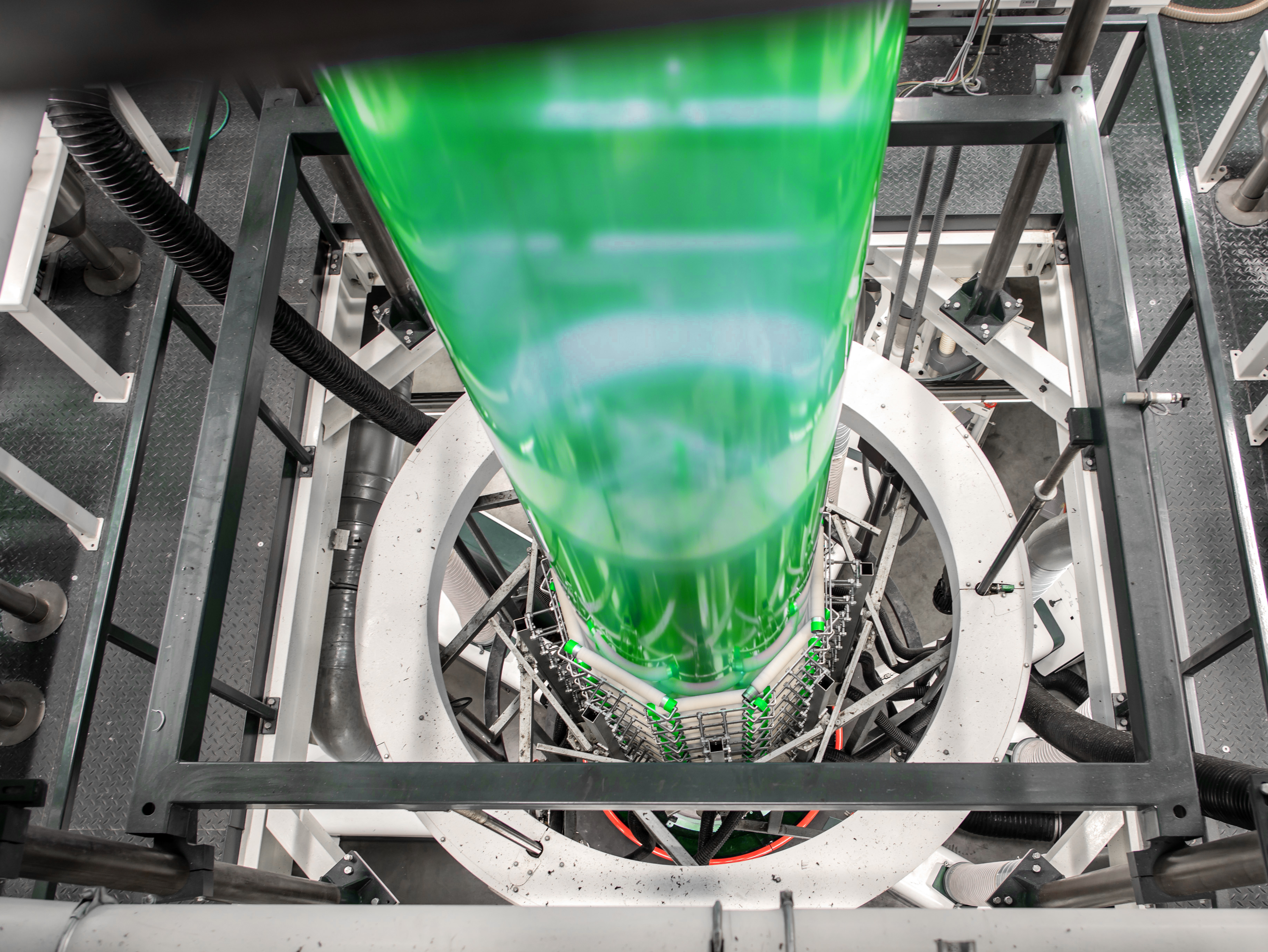

Flow Pack PurePP –

innovative design with added value

Flow Pack PurePP an unconventional packaging concept for ground meat based on polypropylene. Compared to conventional tray packaging, this practical tubular bag reduces the amount of material used by approximately 60 percent.

- 60% less material

- Optimum product protection

- Presentation at the POS

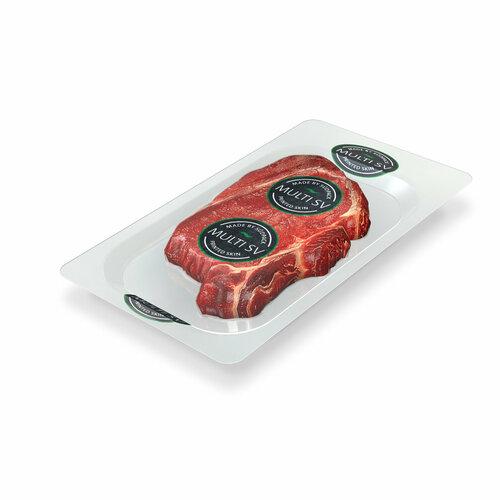

Our Multi SV-Skin – perfectly adapts

The flexible top web tightly encloses the product without deforming it. It is suitable for thermal applications, deep freezing as well as storage at room temperature. Steaks, mussels or sausage look natural and appetizing at the POS.

- Clear view of the product

- Vacuum for extended shelf life

- Ideal for shipped products

Multifol® GA – a versatile classic

These thermoformable high-tech films with a wide sealing range and high puncture resistance are ideal for producing soft and vacuum packaging. For fish, meat, sausage and dairy products. And also for deep freezing or the microwave.

- High level of mechanical strength

- Suitable for freezing and microwaving

- Optional peel function

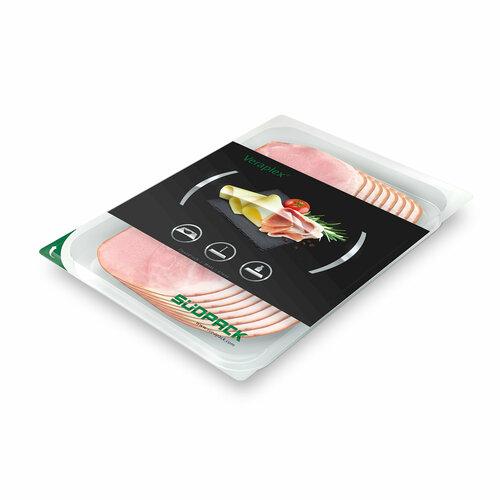

Veraplex world – less is more

As little packaging as necessary, as much functionality as possible. With a 50% reduction in film thickness, our high-performance Veraplex films are not only environmentally friendly, but also enhance packaging efficiency – while providing the same level of product protection.

- Lower material consumption

- More running meters per reel

- Cutting-edge extrusion technology